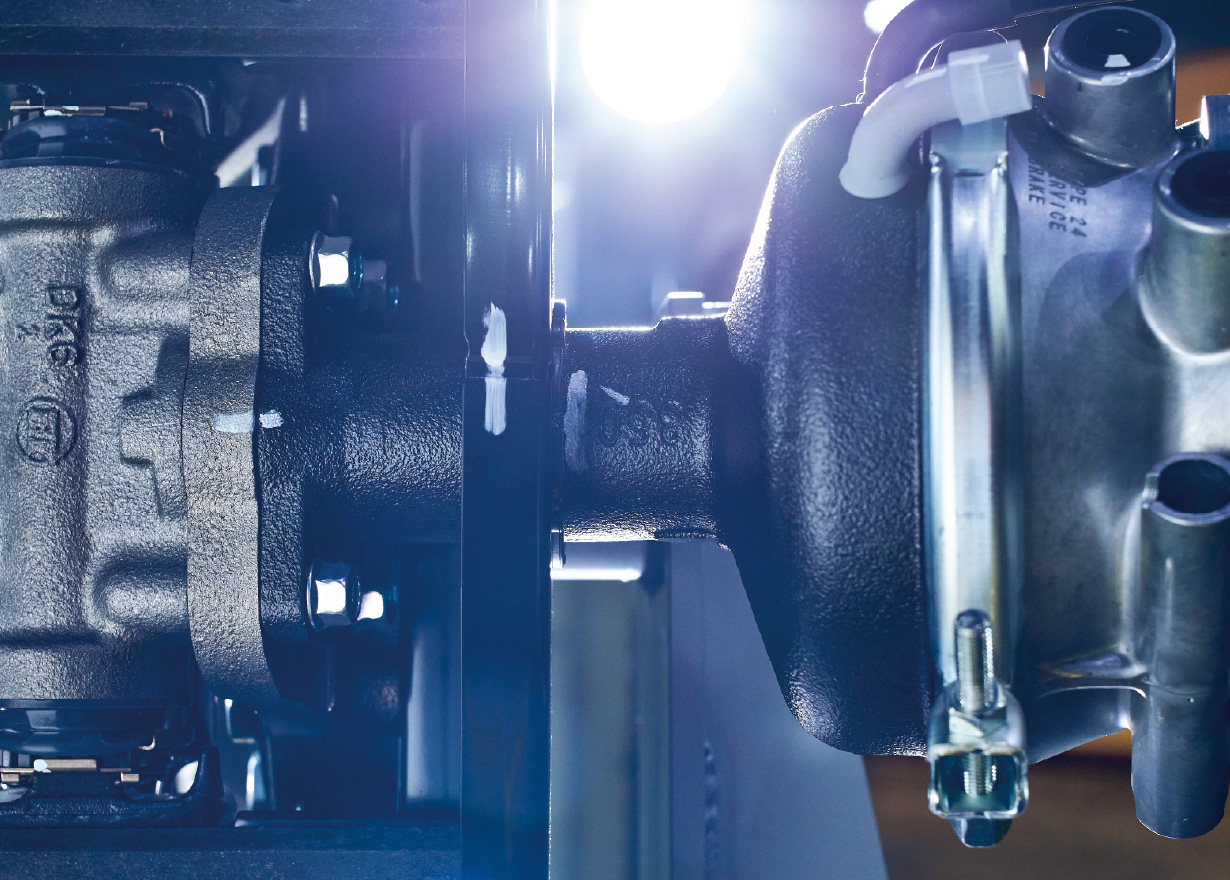

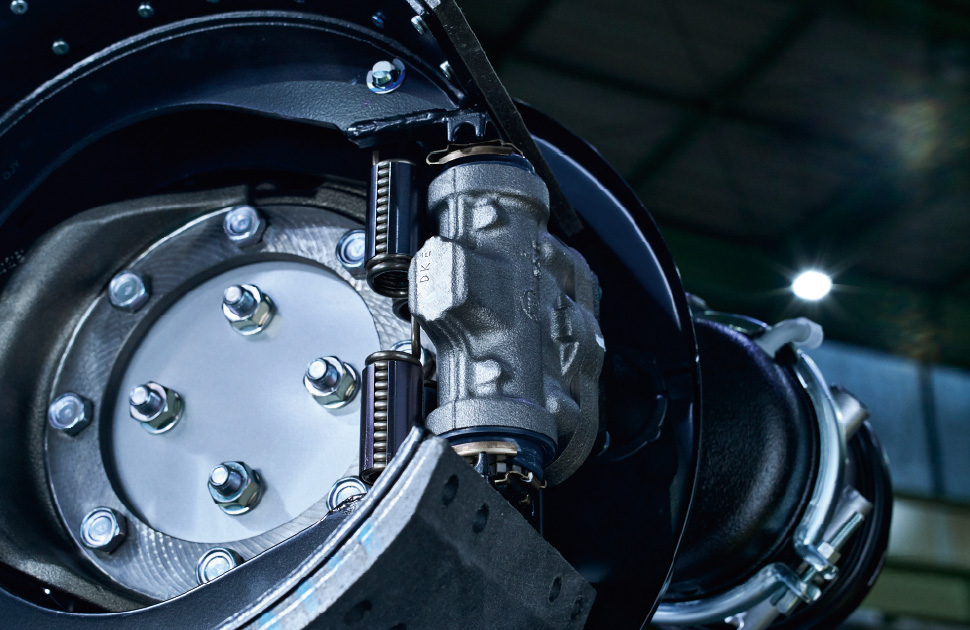

Since its founding in 1949, TBK has continuously taken responsibility for quality and pursued innovation in essential components such as brakes and pumps for commercial vehicles. Even as the way we move continues to change, our mission remains the same. With a steadfast commitment to manufacturing excellence, we continue to support mobility from the ground up by meeting the needs of the future, such as electrification and carbon neutrality.

TBK supports society with three strengths to realize a safe and sustainable future.

The reliability of our products that support mobility. The innovation of technologies that drive change. Harmony with the environment to pass on to future generations.

We continue to meet every challenge with the power to support.

Please select from the following options according to your inquiry.